Technical specifications

| MAX OUTPUT | 15 Kg/min @ 110 bar 9 Kg/min @ 160 bar 7 Kg/min @ 240 bar |

| ELECTRICAL CONNECTION | 3PE 400V 50/60 Hz 3PE 230V 50/60 Hz |

| HEATING POWER | 12 kW |

| MOTOR POWER | 4 kW |

| HOSE HEATING | 3 kW |

| MACHINE CONSUMPTION | 38,4 A / 66,6 A |

| MAXIMUM HOSE LENGTH | 93 m (for foam) 78 m (for polyurea) |

| WEIGHT | 261 kg (without oil) |

| OIL CAPACITY | 59 l |

| DIMENSIONS | H= 1352 mm W= 945 mm L= 745 mm |

Documentation

Features and Characteristics

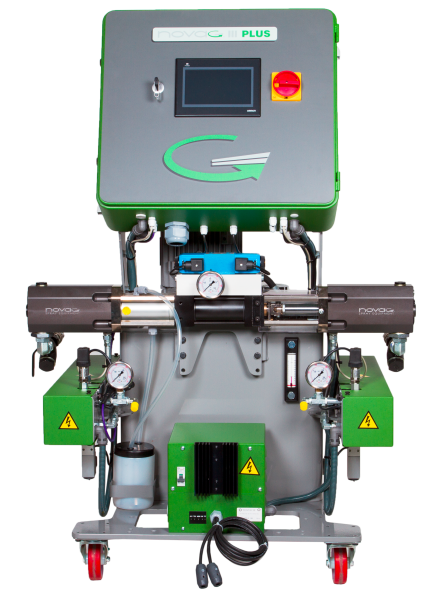

The new NOVAG III PLUS hydraulically driven proportioning unit has been designed and manufactured to fulfil the most demanding requirements of industrial foam in place applications of two component systems requiring high dosing precision to assure the best mixing quality of the chemical components. Its particular configuration facilitates easy access to all its components, simplifies the control functions and significantly reduces maintenance time.

Primary Heating System

The primary heating system consists of two separate independent tube heaters. Each heater incorporates four 1500W heating elements that supply a total power of 6000W with the necessary control and safety features for the accurate and reliable system performance. The special design of the heaters allows for a ΔT of 50ºC reaching application temperatures of 90ºC under normal environmental temperature conditions.

Hose Heating System

The hose heating system is designed with 3000W isolation transformer that allows the heating of up to 93m (optional 150m). The system incorporates an innovative concept of heated hose in which the copper resistance element is homogenously spread around the hose. This allows accurate and uniform control of the application temperature of the products and avoids the heat concentrations that are produced in traditionally manufactured hoses.

Touchscreen Display

The new Touchscreen Display developed by NOVAG integrates an intelligent PLC software system that gives to the user full control and information before, during and after the application. The new software allows the end user to configure the application parameters of each system that will be automatically regulated by the machine, so that the operator does not have to worry about the correct temperatures and pressures specified for each and every system used. A sophisticated alarm system warns the operator of any error in the process to ensure the right application of the system. As an additional feature, a phase connection alarm is incorporated into the design to avoid costly repairs from errors when plugging the machine into the electrical supply.

This revolutionary new system can be connected and controlled trough an external computer, tablet or smartphone. The machine display will be reproduced in the selected device for a remote control of the unit, avoiding the need to have an operator in front of the machine at any moment to monitor or to make any changes.

Monobloc Pumps with Anti-Leak System

This new Monobloc pump incorporates a revolutionary Anti-Leak System.

A double acting hydraulic cylinder drives two directly opposed chemical proportioning pumps. This new reinforced design eliminates asymmetrical loads and assures prolonged life of the pump packing seals as well as assures a constant stabilized pressure in order to achieve perfect mixing of the chemical components. Several pump sizes are available to obtain different volumetric ratios.

Novag Logger

The Best Application Control Tool

It is an electronic system for data acquisition.

During the working sessions of the proportioning unit, all measuring values and parameters like temperatures, pressures, working time, alarms, ratio and product consumption will be captured and stored through a USB device (Pen Drive). Through the Novag Logger software, captured data can be visualized, analyzed, printed and represented graphically into any personal computer.